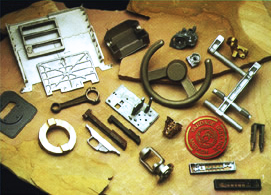

Castings

We find metal castings fascinating because there are often opportunities to save cost by moving to a different metal casting technology than perhaps a client had originally envisioned. On the buttons to your left you will find information about some of the casting processes we get involved with. Below you will find mechanical properties of some of the most commonly specified casting alloys.

| Alloy | Process | Tensile (ksi) | Yield (ksi) | Elongation | Hardness |

|---|---|---|---|---|---|

| 319 Alum | Sand | 23 | 13 | 1.5% | 55-85 BHN |

| 356-T6 Alum | Sand, Permanent Mold, Investment | 30 | 20 | 3.0% | 55-90 BHN |

| 535 Almag | Sand | 35 | 18 | 9.0% | 60-90 BHN |

| Ductile Iron | Sand, Investment | 58-60 | 30-35 | 8-20% | 140-200 BHN |

| 380 Alum | Die | 46 | 23 | 3.5% | 80 BHN |

| Zamac 3 | Die | 41 | 32 | 10% | 82 BHN |

| CF8 304 SS | Investment | 70 | 30 | 35% | 140 BHN |

| CF8M 316 | Investment | 70 | 30 | 30% | 170 BHN |

The information above is believed to be accurate but is in no way warranted.

These are but a few of the alloys we get involved with. Please get in touch with us so we may get your casting project started on solid footing.

356 T6 vs 6061-T6

This question often comes up when considering casting a part vs. machining. The following information is presented for reference.

| Property | 356-T6 | 6061-T6 |

|---|---|---|

| Ultimate Tensile (MPa) | 260 | 310 |

| Yield (MPa) | 160 | 270 |

| Elongation (%) | 4 | 15 |

| Density (g/cm 3) | 2.69 | 2.70 |

| Fatigue Strength (MPa) | 60 | 97 |

| Strength/Weight (KN-m/Kg) | 97 | 115 |

| Shear Modulus (GPa) | 26 | 27 |

| Thermal Conductivity (W/m-K) | 150 | 170 |

| Electrical Conductivity (% IACS) | 40 | 43 |

Glossary of Casting Terminology

Alloy A metallic solid created by combining two or more metals or adding a non-metal to a metal for the purpose of enhancing its properties for the end use

As-cast condition Casting without subsequent heat treatment

Casting A process used to form solid metal shapes out of molten metal. The molten metal is poured into a cavity or a mold.

Charge Metal and alloy materials that make up the composition of a melt.

Checking Fine cracks on the surface of a die which produce corresponding raised veins on die castings. Checking is caused by repeated heating of the die surface by injected molten alloys.

Cold shut A surface imperfection due to unsatisfactory fusion of metal.

Cope The top half of a horizontally parted mold.

Core A sand or metal insert in a mold to shape the interior of the casting or that part of the casting that cannot be shaped by the pattern.

Draft Taper on the vertical sides of a pattern or corebox that permits the core or pattern to be removed.

Drag The bottom half of a horizontally parted mold.

Ductile iron A cast iron that has been treated while molten with an element such as magnesium or cerium to induce the formation of free graphite as nodules or spherulites. This imparts a measurable degree ductility to the cast metal as opposed to grey iron which is more brittle.

Ejector marks Marks left on castings by ejector pins.

Ferrous Metal An alloy that has iron as the predominant metal.

Finish allowance The amount of stock left on the surface of a casting for machining.

Flash A thin section of metal formed at the mold, core, die joint or parting in a casting. Flash usually forms when the cope and drag do not match completely or when the core and the coreprint do not match.

Gas Porosity A condition in a casting that occurs when gas is trapped in molten metal or as a result of mold gasses that evolved when the casting was poured.

Gating Systems The channel(s) that allow the molten metal to enter the mold cavity.

Green Sand Moist sand that is bonded by a mixture that contains silica, clay, carbonaceous material, and water.

Gross Weight of Casting The weight of the casting which includes the actual product plus the metal in the gating system as poured.

Hot Isostatic Pressing The process of using high hydrostatic pressure and high temperature to compress fine particles into coherent parts

Impurity An element that is allowed into a metal or alloy. Impurities slightly change the properties of the material in some circumstances and can completely damage it in others.

Inclusions Particles of slag, refractory materials, sand or deoxidation products trapped in the casting during pouring solidification.

Investment Casting A casting process that uses a wax or thermoplastic pattern and is surrounded in a refractory slurry to form a mold. Once the refractory slurry is dry, the wax or plastic is melted out and the mold is formed. Molten metal is then poured in to fill the area that was previously filled with wax.

Jobbing Foundry A foundry that creates a wide variety of castings, in small quantities for a range of customers.

Ladle The name for a variety of receptacles used to move and pour molten metal during the casting process.

Loose Pattern The cheapest pattern to make, has the shape of the casting without forms for sprues, risers, etc. attached.

Machining Allowance The amount by which dimensions of a casting are made oversize to provide excess stock for machining

Master pattern The object from which a die or production pattern can be made; generally a metal model of the part to be cast with process shrinkage added.

Metal Yield The difference between the weight of a finished casting and the total weight of the metal poured.

Mold The cavity that the molten metal is poured in to form the final shape. A mold usually consists of a top and bottom piece made of sand or ceramic material.

Mounted Pattern A pattern that is fastened permanently to a board or match plate.

Net Weight of Casting The final weight of a casting that is determined once all of the excess metal from the gating system has been removed.

Non-ferrous Metal An alloy that doesn’t have iron as the predominant metal.

Parting Line The line where parting surface meets with the casting surface of the mold

Pattern A replica of the object to be cast, used to prepare the cavity into which molten material will be poured during the casting process

Pattern Draft The taper allowed on the vertical faces of a pattern to enable removal of the mold or die.

Rapid Prototyping The computerized equipment that builds a three-dimensional model of a casting from a CAD drawing.

Sand Casting Producing metal castings out of sand molds.

Sand inclusions Cavities or surface imperfections on a casting caused by sand washing into the mold cavity.

Sand Reclamation Processing used sand grains into usable forms so that they can be used in the casting process as a replacement for new sand.

Scrap All non-product metal produced during the casting process.